FIRE PROTECTION SOLUTIONS FOR MOTOR VEHICLES

Due to ever more compact and efficient engines, which also have to meet stricter and stricter environmental requirements, the risk of fire is increasing.

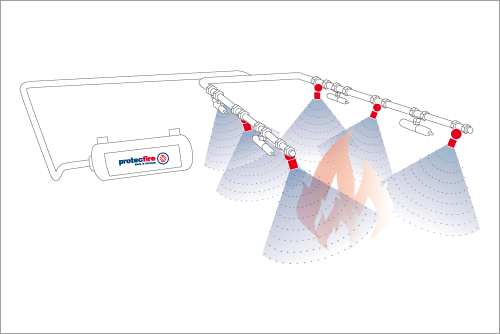

As a result of protecfire‘s consistent development of the extinguishing technology for machine and engine protection that was proven reliable and approved for use in the mining industry, the new and peerless detexline (detection – extinguishing) has been designed.

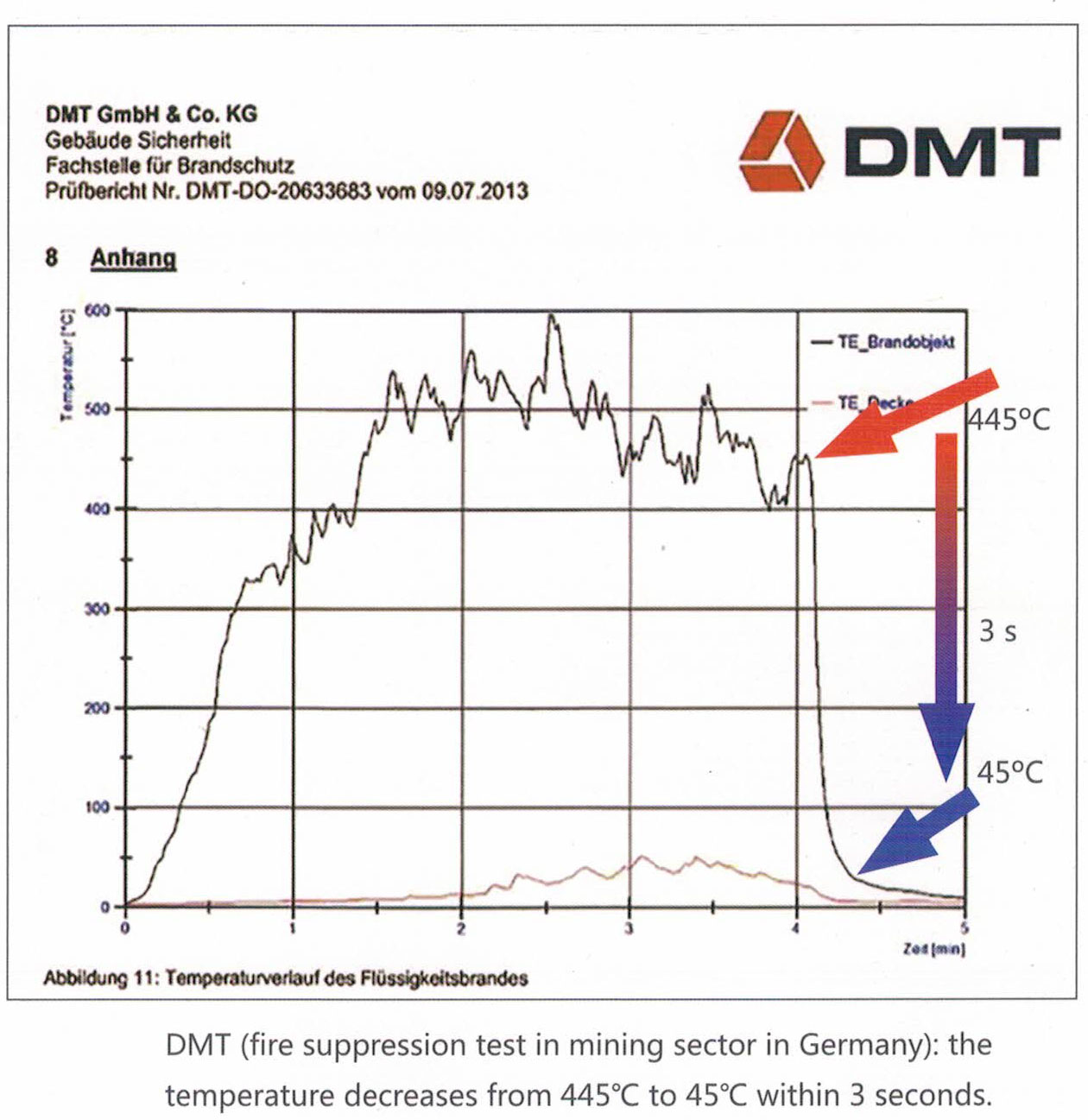

To prove the system‘s effectiveness, protecfire has had the system certified in rigorous tests by the following officially recognized institutions:

- DMT for mining certification

- VdS for industrial kitchens

- SP4912 for engine protection

The fire suppression system has been designed for use as a fixed fire suppression system in all kinds of vehicles, such as:

- Buses

- Lorries transporting hazardous materials

- Tunnel Vehicles

- Construction Equipment

- Mining Equipment

- Forestry Equipment

- Rail Vehicles

- Vehicle-mounted cranes

- Pleasure Boats and Yachts

- Harvesting Equipment

PRODUCTION DESCRIPTION

- Made in Germany

- Approved and Certified by German and International Bodies (DMT, VdS, SP4912, UNECE, among others)

- No electricity needed (continued operations during power failure)

- Minimal Maintenance required

- Easy Installation

- Reliable under extreme conditions

- Resilient to external influences, vibrations and impacts

- Patented Technology for Detector

- Agent: Available in either Liquid or Powder form

Advantages

- No replacement of components for 10 years

- Simple installation and (re-)fitting

- Almost maintenance-free – optionally, maintenance can be carried out by the customer‘s own personnel

- Exact and ultra fast fire detection through patented fire detection element

- Successfully tested according to SP 4912

- Depressurized while in operational mode

- No external power supply needed

- Long extinguishing agent discharge times (up to 90 sec.)

- Various trigger temperatures possible in one system

- Use at -30°C to 80°C ambient temperatures

- Unique hybrid system due to combined gas and finespray suppression system